PM (Polarization Maintaining) fiber array is crucial for photonic waveguide devices, WDM (Wavelength Division Multiplexing), and AWG (Arrayed Waveguide Grating) applications. It can connect with the waveguide to control light transmission and use a V-Groove substrate to achieve accurate fiber position and high reliability. This article delves into the intricacies of PM fiber arrays.

What is a PM Fiber Array?

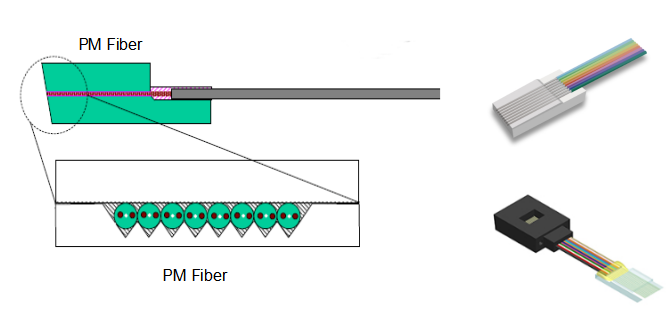

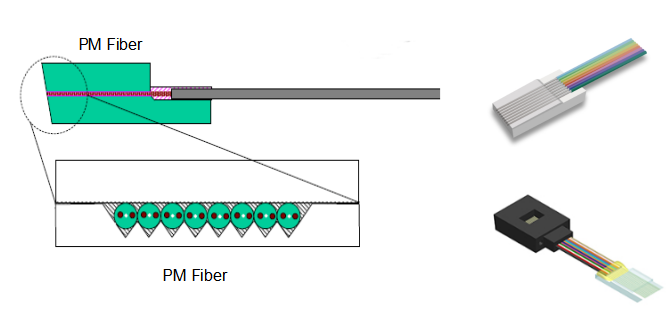

PM fiber array is an array formed by installing a bundle of optical fibers or a fiber ribbon on the substrate at specified intervals using a V-Groove substrate. It has a substrate, a pressing plate, and an optical fiber. Usually, a plurality of grooves are cut in the base of the substrate, the pressure plate is pressed, and the optical fiber inserted into the groove is fixed.

How Does the PM Fiber Array Work?

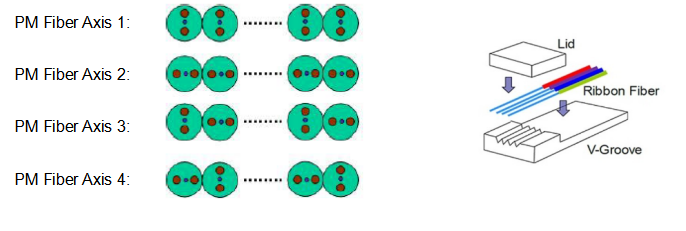

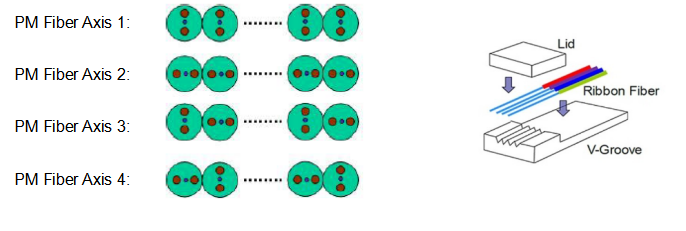

PM fiber array uses a high-precision V-Groove quartz substrate to locate the fiber cores and accurately polish the surface. It ensures the direction of linear polarization and improves the coherent signal-to-noise ratio. PM fiber array has several substrate materials such as Glass, Quartz, or Silicon. PM fiber array employs a V-groove to install a PM fiber ribbon on the array substrate, which can achieve high-density parallel transmission while ensuring the polarization stability of light waves.

How to Realize the Positioning of PM Fiber Array?

PM fiber array mainly depends on precision engraved V-shaped grooves to achieve positioning. The V-groove uses a cutting process to achieve precise fiber positioning. The bare fiber part with the fiber coating removed is placed in the V-groove. This process requires ultra-precision processing technology to accurately position the fiber core in the V-groove to reduce the connection loss. Then press the parts by the pressurizer fixed with an adhesive and optically polish the end face to form an optical fiber v-groove array. The substrate material will affect the optical properties of the PM fiber array. It is necessary to use a material with a small expansion coefficient to ensure that the PM fiber array is stress-free, highly reliable, and has no fiber displacement at high temperatures. Glass and silicon are commonly used materials, in addition to ceramics, there are conductive substrates and plastic substrates.

Features and Benefits

PM fiber array provides the following features and benefits:

1.Low insertion loss and cost

2.High extinction ratio and return loss

3.High reliability, stability, and coherent signal-to-noise ratio

4.Polarization maintenance, compact size, and accurate fiber core pitch position

5.Fiber types available in SM, MM, PM, and other specialty fibers

Applications

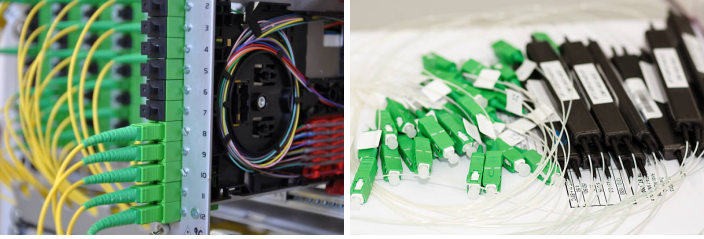

PM fiber array is used in fiber optic sensing, photonic waveguide devices, WDM/DWDM systems, AWG, fiber collimators, PLC splitter, optical switches, optical transceiver modules, power monitoring systems, interferometry, fiber optic gyro, fiber optic hydrophones, optical signal distribution, coherent detection systems, long-haul, metro networks, data center, etc.

Conclusion

PM fiber array is an indispensable component in modern photonics, serving a vital role in preserving the polarization state of light. As technology advances, PM fiber arrays will likely continue to play a crucial role in enabling various cutting-edge photonic applications.

Sun Telecom specializes in providing one-stop total fiber optic solutions for all fiber optic application industries worldwide. Contact us if you have any needs.

Position :

Home>

News & Tutorial

>Products

Position :

Home>

News & Tutorial

>Products

Position :

Home

>Products

Position :

Home

>Products

ics@suntelecom.cn

ics@suntelecom.cn  +86 18964888554

+86 18964888554 Building No.145, Lane 666 Xianing Road, Jinshan Industrial Zone, Shanghai 201506, China

Building No.145, Lane 666 Xianing Road, Jinshan Industrial Zone, Shanghai 201506, China