5G, IoT (Internet of Things), and data center applications accelerate the development and expansion of fiber optic networks, increasing the demand for fiber optic cables. MTP/MPO fiber optic cable that houses more fibers in a multi-fiber MTP/MPO connector improves network stability and sustainability. To ensure its best optical performance, it is essential to test MTP/MPO fiber optic cables. This article will focus on tests for MTP/MPO fiber optic cables.

What is MTP/MPO Fiber Optic Cable?

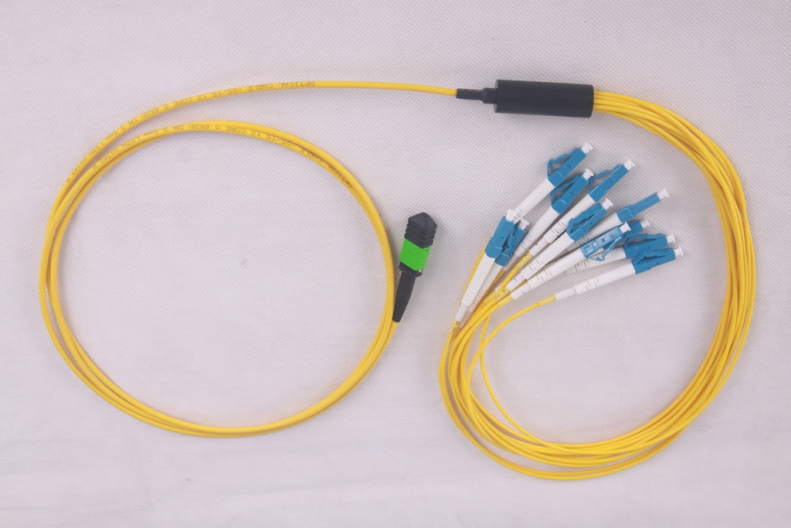

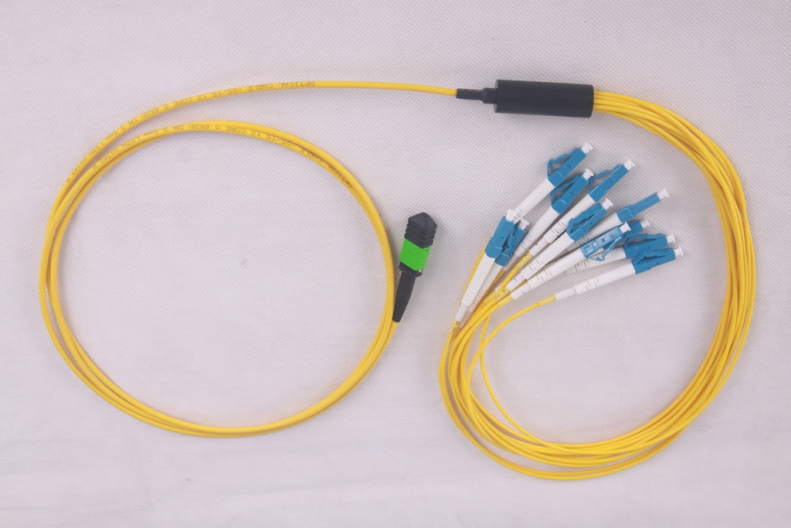

MTP/MPO fiber optic cable consists of MTP/MPO connector and optical fiber. MTP/MPO connectors have a female type (without pins) or a male one (with pins). It is designed for high-density fiber patching in data centers, which can save space and reduce cable management issues.

MTP/MPO Fiber Optic Cable Testing Best Practices

Testing MTP/MPO fiber optic cables helps to contribute to performance, reliability, and manageability. Following these basic MTP/MPO fiber optic cable testing best practices will result in more reliable and efficient network deployments.

1) Inspection and Cleaning

Inspection is critical to verify the cleaning work. Fiber end-face inspector used to inspect fiber optic end faces on patch cords and MTP/MPO connectors. MTP/MPO connectors are sensitive to dirt and contamination, needing strict inspection and cleaning before testing. Essential is a high-quality microscope to check the MTP/MPO connectors. If the MTP/MPO connectors are dirty, clean them with dry cleaning tools, such as a cassette cleaner and an MTP/MPO pen cleaner. They wipe away contaminants from the MTP/MPO connector end face. If MTP/MPO connectors are still not clean, clean them with cleaning wipes or foam swabs. Inspection and cleaning need to be performed on both ends, every time MTP/MPO cables are connected.

2) VFL Testing

The fiber continuity of MTP/MPO cables can be tested using a VFL (Visual Fault Locator). VFL is a visible light source (LED or laser diode) that injects visible light energy into an optical fiber. It enables fiber identification from one end to the other end. In addition, it helps to identify and locate fiber link faults during testing, such as fiber bends, breaks, and faulty connectors.

VFL does not have an MPO interface, but we can use two MPO-LC harness patch cords: The MPO side is connected with the MPO cable by an MPO adapter, and insert the LC connector on the optical interface of VFL. If the cable does not break, the user will see a red light on the LC connector on the other/far side. If the fiber breaks inside, then there should be no red light on the far side of the LC connector. In addition, VFL is used to check whether the polarity of the MPO cable is right or not.

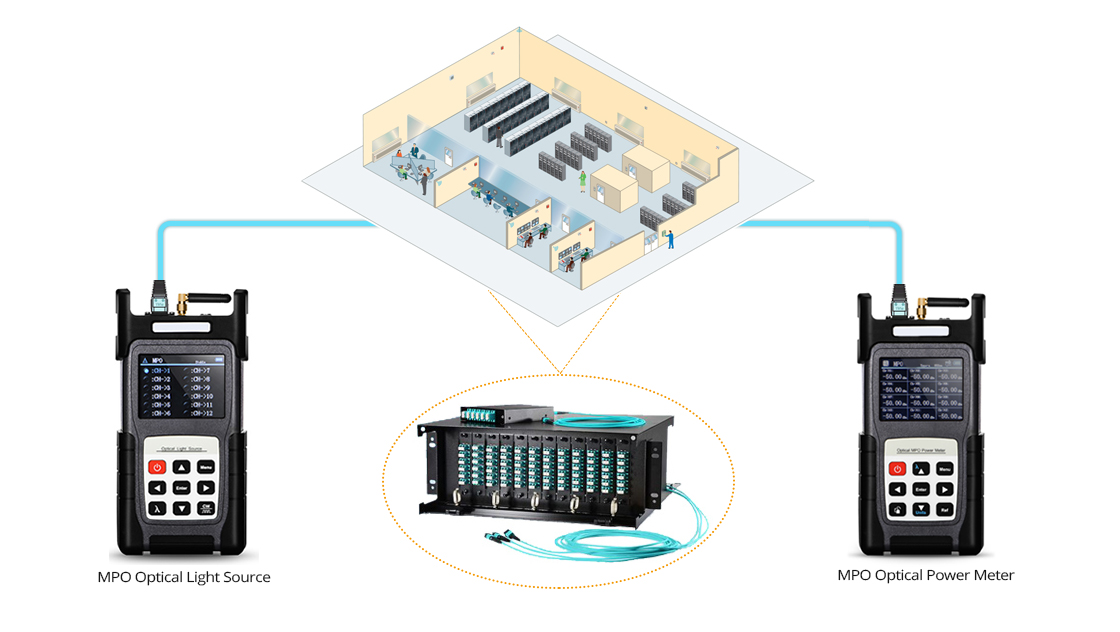

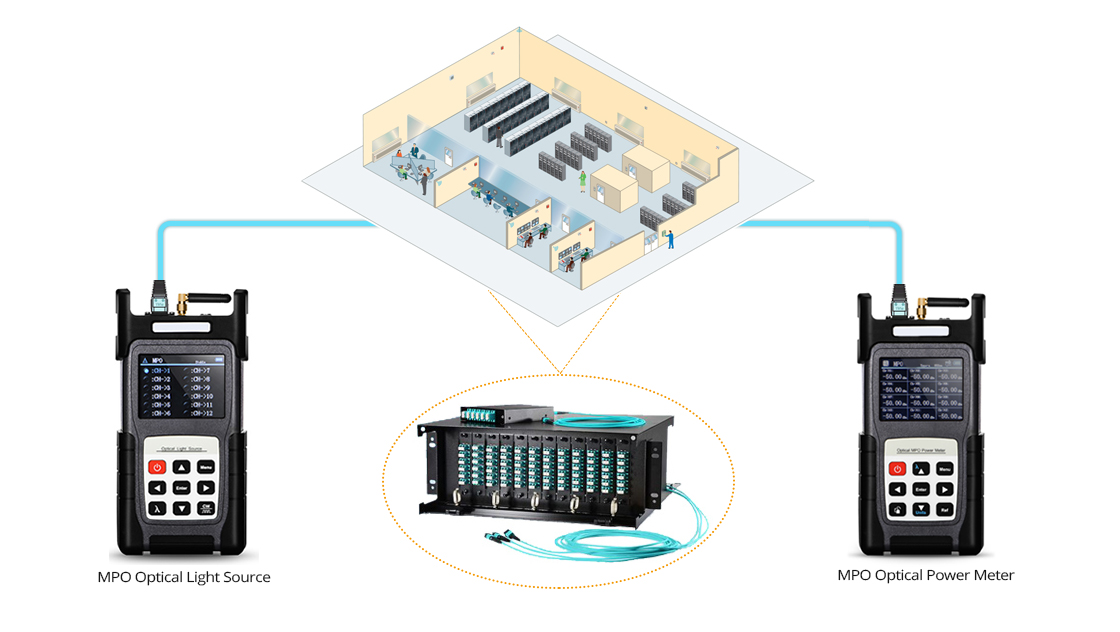

3) Optical Light Source and Optical Power Meter Testing

An optical light source is a testing instrument used to measure the fiber optic loss and check continuity for single-mode and multi-mode fiber optic cables. It provides a high-performance testing solution for the fiber optic network together with an optical power meter (OPM). OPM is a testing instrument used to accurately measure the power of fiber optic equipment or the power of an optical signal passed through the fiber optic cable. Optical light source and OPM for MTP/MPO cable help quantify the insertion loss of the link and ensure an applicable optical power budget. The near side and the far side of the MPO link are standard SC/LC connectors.

Conclusion

In conclusion, MTP/MPO fiber optic cable testing is the key to better performance measurement. As technology advances, methods and equipment for fiber optic testing will continue to evolve. There will be more advanced and effective MTP/MPO cable testing methods available in the future.

Sun Telecom specializes in providing one-stop total fiber optic solutions for all fiber optic application industries worldwide. Contact us if you have any needs.

Position :

Home>

News & Tutorial

>Products

Position :

Home>

News & Tutorial

>Products

Position :

Home

>Products

Position :

Home

>Products

ics@suntelecom.cn

ics@suntelecom.cn  +86 18964888554

+86 18964888554 Building No.145, Lane 666 Xianing Road, Jinshan Industrial Zone, Shanghai 201506, China

Building No.145, Lane 666 Xianing Road, Jinshan Industrial Zone, Shanghai 201506, China